Project Overview

The objective of this project was to fabricate, weld, and install reinforcement beams and deck plates on the TED Platform as outlined in DWG No. TWI-TT-TEA-PER-DW-I-003 Rev 02. Given the platform’s constraints and crane reach limitations, SMSCL was responsible for both onshore fabrication and offshore installation, ensuring compliance with industry standards and PerencoTT’s safety and quality requirements.

How Did SMSCL Help?

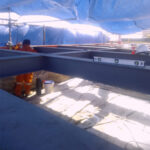

Our team managed the entire scope, from material handling and fabrication to offshore execution. We prefabricated main beams (W10 x 33), angles, deck plates, and handrails, performing blasting and painting at our shop facility before delivering them to Galeota Warehouse using certified Cargo Carrying Units (CCUs).

For offshore execution, SMSCL mobilized a highly skilled team equipped with scaffolding, rigging, welding, and NDE expertise. Due to crane reach limitations, we implemented advanced rigging solutions to install the prefabricated beams and deck plates safely. All structural welding followed AWS D1.1 codes, with 100% visual inspections, 100% MT & UT flaw detection on primary joints, and 20% MT on secondary welds.

Our safety-first approach included erecting scaffolding and protective barriers to create a safe working zone near hazardous areas. Additional gas monitors were deployed for continuous atmospheric monitoring. Offshore logistics were carefully managed to ensure seamless material transport, personnel transfers, and compliance with PerencoTT’s site access protocols.

Upon project completion, SMSCL submitted a comprehensive dossier, including material and welder certifications, PQRs, WPS, NDE reports, and completion certificates to validate project execution.

At SMSCL, we are committed to delivering high-quality structural solutions, maintaining strict safety standards, and ensuring operational efficiency in offshore environments.

SMSCL Project Scope:

- Onshore Fabrication & Preparation:

- Pre-fabrication of beams, deck plates, and handrails as per DWG No. TWI-TT-TEA-PER-DW-I-003 Rev 02.

- Blasting and painting of fabricated structures following NACE SSPC SP-10/NACE 2 standards.

- Delivery of materials to Galeota Warehouse in certified CCUs.

- Offshore Installation & Execution:

- Mobilization of tools, equipment, and materials to the TED Platform.

- Installation of prefabricated beams, deck plates, and handrails using advanced rigging solutions.

- Execution of welding, NDE, and final painting to offshore specifications.

- Scaffolding erection and demolition of obstructions for worksite clearance.

- Implementation of safety barriers and continuous gas monitoring in hazardous zones.

- Quality & Compliance:

- Compliance with AWS D1.1, AISC, and PerencoTT’s coating guidelines.

- NDE inspections: 100% visual, 100% MT & UT on primary joints, 20% MT on secondary welds.

- Submission of quality plans, ITPs, daily progress reports, and inspection records.

- HSE & Logistics:

- Adherence to PerencoTT’s Minimum Offshore Site Standards (MOSS) and Safe Systems of Work.

- Offshore transfers via Galeota Base following PerencoTT’s designated logistics schedule.

- Compliance with OGUK medical requirements and full vaccination policies.

- Strict adherence to liquidated damages policies for project delays.